Precision Stamping Engineering & Design

At MTSI we work closely with our customers throughout the entire precision stamping and tooling process.

We are committed to an engineering and design implementation that increases manufacturability and reduces part costs over the life of your products.

The MTSI advantage starts with our superior engineering and design services, which translate into the highest quality tooling fabrication and ultimately the best possible precision parts for you.

MTSI was built upon our reputation for excellent design and craftsmanship, and we continue to honor that legacy today!

High-Quality Engineering Process

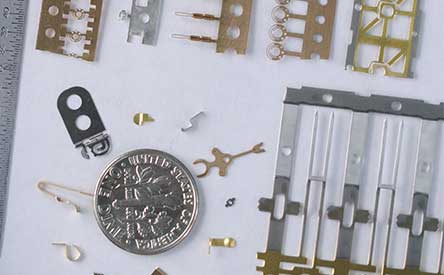

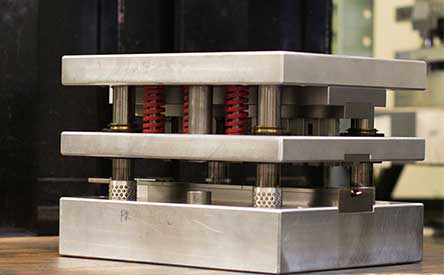

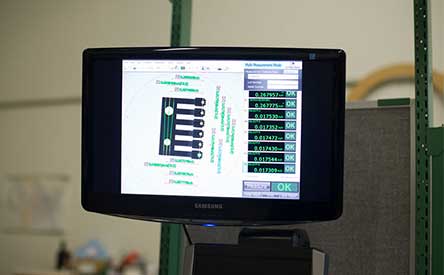

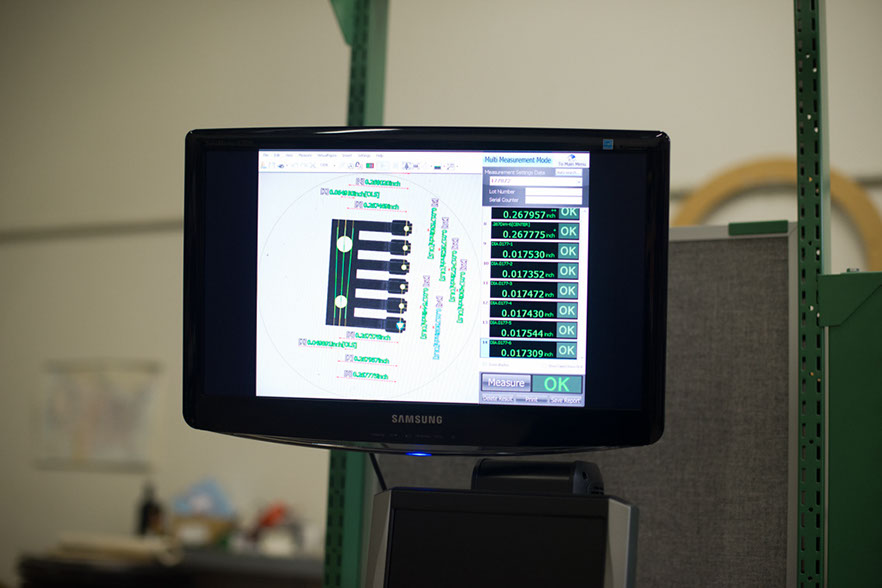

MTSI is proud to be known as one of the best progressive die builders in the industry! We build dies with the highest quality tool steel and carbide components to tolerances of +/- .0001”. Precision-built four-post die-sets are guided on Swiss-made pins, bearings, and guide sleeves ensuring 100% accuracy on die alignment for the life of your product. This precision, pride and detail goes into every tool MTSI builds and runs.

Computer-Aided Design for Superior Precision Stamping

At MTSI, we work strictly to customer-designed part prints. Our AutoCad and SolidWorks design software allows us to do quick part analysis and rapid project quoting, as well as to rapidly modify parts and tooling while keeping the project on schedule. Our experience and design systems also allow us to make and implement suggestions for increasing manufacturability and reducing costs in the quoting stage.

MTSI utilizes several post stamping finishing vendors from the very best in gold plating to simple solder plating.

MTSI can also provide design and build of post stamping tooling for customer use. This can be for forming leads, trimming leads, de-gating, and separating parts for assembly line packaging by our customers.

We also give critical consideration to tolerances, finishing requirements, and potential post-stamping assembly needs. This attention in the design stage to total project parameters helps to eliminate potential problems and reduce costs during this least expensive stage of product development.

Whether your project is a piece part, a reel-to-reel application, or rapid prototyping, we provide the best solutions for your total project needs.

Contact MTSI today for a FREE design evaluation! 763.754.1045

Rose Creek Anglers, Inc.

When we transferred production of our programming cables from an outside vendor to our in-house production, Metric Tool provided the most critical part of the solution. Their staff worked with me in the contact design process which greatly reduced our manufacturing costs. Metric Tool places a higher value in their relationships with companies than with monetary expectations. Since the time of the programming cable project, they have provided a great deal of die design advice.

Resistance Technology

“Metric Tool & Stamping has been supplying us with precision micro-stampings for our electronic control assembly for more than twelve years. Their stampings are always very precise…especially in the critical areas of the part. For example, they produce a complex insert stamping on one of our switch lead frames that they consistently hold to within .0001. Metric is one of the best tool houses in the business.”

Omnetics Connector Corp.

“[MTSI] has been a principal supplier to Omnetics for over ten years. Metric has tooled and produced a variety of close-tolerance stamped electrical contacts critical to Omnetic's needs. They've demonstrated their skill in doing the tough parts with a visible pride in workmanship. I value our good working relationship.”

Rollerblade, Inc.

Metric supplies us with several stamped parts for our in-line skates. As the world leader of in-line skates, we require quick response on large quantities. [MTSI] has always delivered on time, and [they are] extremely responsive to our needs. They always call first when questions come up. We definitely appreciate working with a solid company like Metric.”