If you’re considering hiring a professional metal stamping service, it’s important to understand the process, its history, and what to look for in a provider. Stamped metal is used in countless industries today, from automotive manufacturing to household appliances, so knowing what you’re paying for helps you make the best choice.

This guide will walk you through the history of metal stamping, its modern applications, common misconceptions, and the process itself—so you can confidently find the right company for your project.

A Brief History of Metal Stamping

The origins of metal stamping go back to the 1880s, when mass-produced bicycles required stamped parts. At the time, stamping began replacing machining and die-forging because it was faster and more cost-effective.

By the 1890s, the U.S. was importing stamped bicycle parts from Germany. Soon after, the automotive industry adopted stamping, especially as Ford Motor Company scaled up production with assembly lines. While not as strong as die-forged components, stamped parts offered sufficient quality at a much lower cost—making them essential in manufacturing.

Stamped Metal in Everyday Life

Today, stamped sheet metal is everywhere. You’ll find it in:

-

Household appliances – washing machines, dryers, and kitchenware.

-

Automotive parts – critical components in cars and trucks.

-

Everyday items – silverware, pots, pans, cigarette lighters, and shells.

-

Technology – computers and modern electronics.

Stamped metal has become a cornerstone of modern manufacturing, proving its versatility across industries.

Common Misconceptions About Metal Stamping

Many people assume metal stamping is a dirty, unskilled factory job. In reality, metal stamping requires expertise, precision, and problem-solving skills.

-

Skilled stampers rely on creativity and technical knowledge to ensure each part meets exact specifications.

-

The industry is driven more by science than art, requiring a solid understanding of physics and hands-on training.

-

Appearance of tools and workspaces doesn’t matter as much as performance. A well-used tool that creates precise parts is more valuable than one that looks polished but doesn’t deliver.

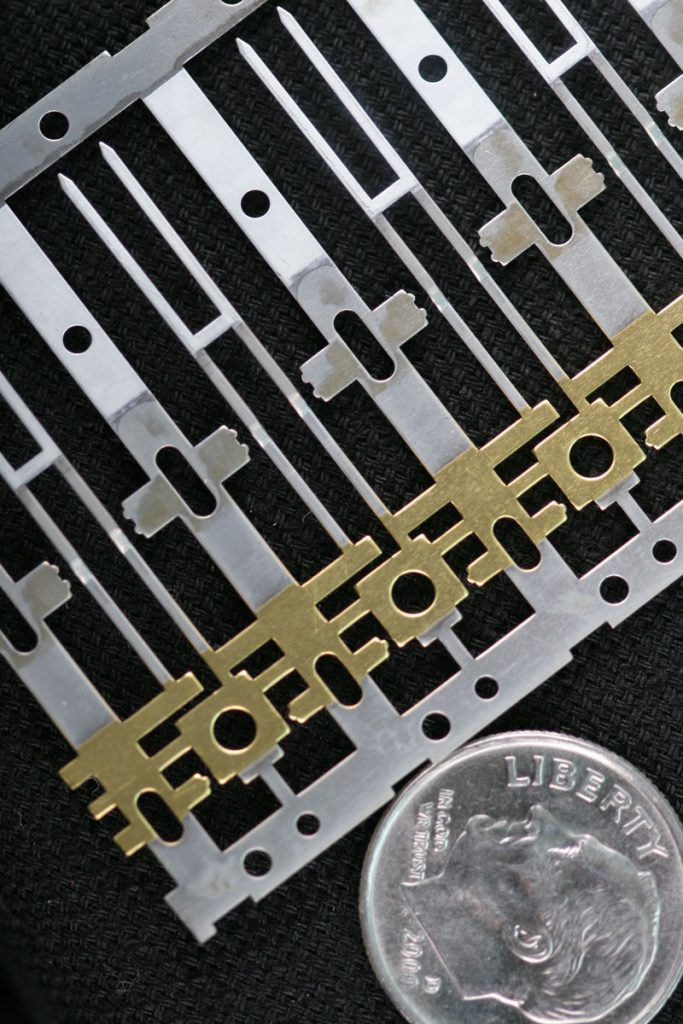

The Metal Stamping Process

While the process can involve a range of machines and techniques, the essentials are always the same:

-

Sheet Metal – The raw material used for stamping.

-

Stamping Dies – Custom-made tools that shape and cut the metal.

-

Stamping Presses – Machines that apply the force needed to form the part.

Most stamping is done using cold forming, which doesn’t require heating the material beforehand. However, friction during the process still generates significant heat. The result is a durable, accurately formed part ready for use.

Choosing the Right Metal Stamping Service

If your business requires stamped metal components, selecting a professional and precise provider is crucial. Poorly made stampings can cost you money, delay production, and even cause equipment failures.

Look for a company with:

-

Proven experience in your industry.

-

Skilled workers and advanced equipment.

-

A reputation for precision and reliability.

Final Thoughts

Metal stamping has a long history of making manufacturing faster, more affordable, and highly efficient. From bicycles and automobiles to household appliances and electronics, stamped metal touches nearly every part of our lives.

When you need stamped metal parts, partner with a professional metal stamping service that delivers quality and precision—because the success of your project depends on it.