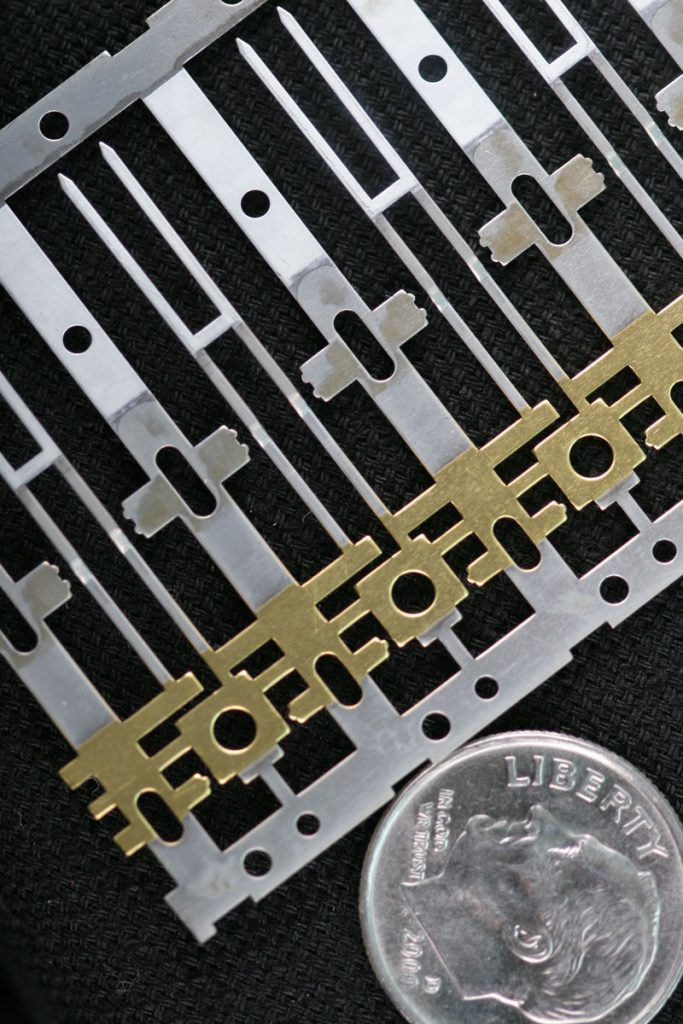

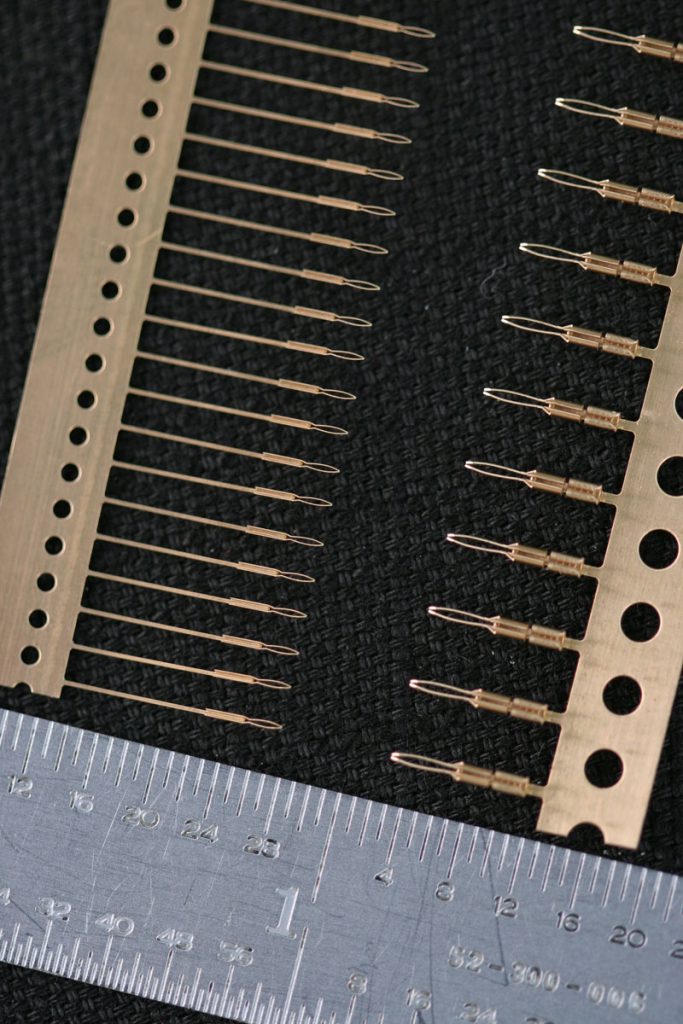

As Metric Tool & Stamping marks its 51st year in business, it’s the perfect time to highlight what makes this industry leader a trusted name in micro stamping services. Metric Tool & Stamping is located in Coon Rapids Minnesota, serving the entire Twin Cities MN area. For half a century, Metric Tool & Stamping has set […]

Why Metric Tool & Stamping Sets the Standard for Micro Stamping Services