Understanding more about metal stamping can help you make a better decision when selecting the right company for your needs. Stamped metal is used in countless ways today, and it’s important to know what you’re paying for. This guide will provide insights into the industry and help you find the best business for your task. For all of your metal stamping needs contact Metric Tool & Stamping Inc, located in Coon Rapids, Minnesota serving the greater Twin Cities MN area.

The History of Metal Stamping

The origins of metal stamping trace back to the 1880s, when mass-produced bicycles led to the creation of the first stamped metal parts. Stamping replaced machining and die-forging, offering a more cost-effective way to produce components.

While stamped parts may not be as strong as die-forged ones, they are more than adequate for many applications. By 1890, the U.S. began importing stamped bicycle parts from Germany, and the demand for stamped components continued to grow with the rise of the automobile industry.

Initially, automakers, including Ford, resisted using stamped parts, favoring die-forged alternatives. However, as customer demand surged, it became evident that stamped metal was essential for efficient production.

Stamped Metal in Today’s World

Stamped metal is now integral to modern life. It’s used in household appliances like washing machines and dryers, as well as everyday items such as silverware, pots, and pans. Even today, many parts of our cars are made using stamped metal.

Beyond the household and automotive industries, stamped metal is found in a wide range of products, including gun shells, cigarette lighters, and even modern technology like computers. Stamped metal truly is everywhere.

Perceptions of Metal Stamping

Despite its widespread use, many people have misconceptions about metal stamping as a profession. Some imagine it as a dirty, low-skill factory job, but in reality, metal stamping requires highly skilled artisans with extensive knowledge and expertise.

Creating stamped metal parts is a complex and hands-on process, requiring creativity and problem-solving. While automation has taken over many manual aspects of the work, human brainpower remains essential to ensure precision and quality. The best metal stampers are experts who strive for perfection in both fit and function.

The Importance of Precision

For stamped metal components to work properly, certain parts must meet exact specifications. Skilled metal stampers invest time and effort into producing parts with the necessary precision while recognizing which areas can be produced with less effort. This balance ensures both performance and efficiency.

Focus on Function, Not Appearance

When evaluating a metal stamping company, don’t be overly concerned with appearances. While a clean workspace and polished tools may seem important, what truly matters is the functionality of the tools and equipment. Focus on a company’s ability to deliver reliable, well-made parts, rather than how things look on the surface.

Metal Stamping: A Science, Not an Art

Although metal stamping can involve creativity, it is primarily a scientific process. Producing high-quality parts requires practical experience and a deep understanding of physics and engineering principles. Master metalworkers combine academic knowledge with hands-on training to ensure every component is made to perform as intended.

The industry demands accuracy and precision, with little room for error. A poorly made die, for example, will not yield successful results, no matter how skilled the worker.

The Metal Stamping Process

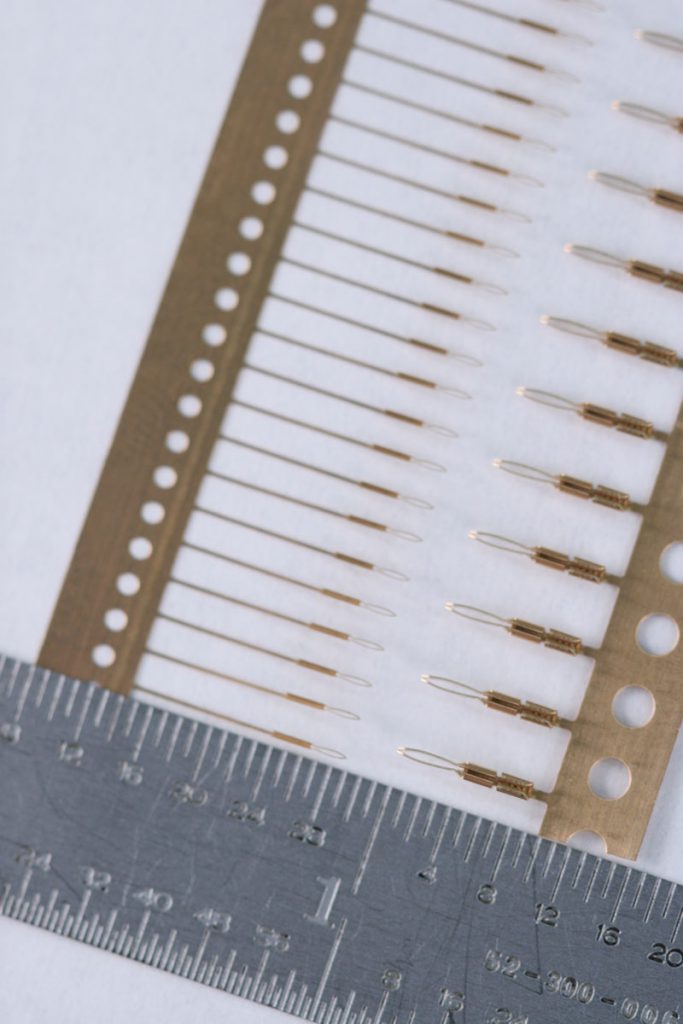

Metal stamping involves three essential components: sheet metal, stamping dies, and stamping presses. The process is designed to shape the sheet metal to the required size and form for its intended use. While some methods involve hot stamping, most metal is shaped using cold forming, which doesn’t require heating the metal.

Despite being called cold forming, the process still generates heat due to friction between the die and the metal. As a result, the metal exiting the die can be quite hot.

Choosing the Right Metal Stamping Service

If your business requires stamped metal components, it’s essential to work with a company known for precision and professionalism. Poorly made parts can lead to wasted money and inefficiencies. Choosing the right service will ensure you receive high-quality components that perform exactly as needed. For all of your metal stamping needs contact Metric Tool & Stamping Inc, located in Coon Rapids, Minnesota serving the greater Twin Cities MN area.