If you’re searching for a custom engineering or design solution, partnering with a computer-aided design (CAD) firm is one of the smartest moves you can make. CAD offers numerous advantages that streamline workflows, improve design accuracy, and enhance collaboration between design and manufacturing teams.

Whether you’re just exploring CAD for the first time or looking to expand its role in your operations, here’s what makes CAD an essential tool for modern businesses. For all of your Metal Stamping needs contact Metric Tool & Stamping Inc, located in Coon Rapids Minnesota serving the entire Twin Cities MN area.

The Benefits of CAD in Engineering and Design

Manufacturing still accounts for roughly 10% of U.S. jobs, and as the industry continues to modernize, many companies are leveraging CAD to drive innovation, reduce errors, and optimize productivity. CAD software bridges the gap between design and production, enabling a more integrated and efficient workflow.

Here are six key reasons to integrate CAD into your design process:

1. Streamlined Design Process

CAD simplifies complex design tasks, allowing engineers and designers to visualize every component of a product in 2D or 3D. Many CAD platforms include animation tools to simulate real-world performance, helping teams understand how parts move and interact.

By documenting each stage of the design process, CAD allows for better collaboration, faster iterations, and fewer errors. The result? A smoother workflow, higher productivity, and better final outcomes.

2. Improved Design Quality

Without clear visualizations, even experienced designers may struggle to produce high-quality work. CAD software enables detailed analysis and simulation, making it easier to predict performance, identify potential weaknesses, and optimize designs for functionality.

Accurate modeling means fewer errors during manufacturing, reduced waste, and better product reliability—saving you time and money.

3. Enhanced Communication

CAD facilitates clear and effective communication among designers, engineers, project managers, and manufacturers. Standardized formats and detailed drawings make it easy to share ideas and ensure everyone is on the same page.

With visual documentation readily available, stakeholders can quickly understand the scope, function, and purpose of every component—leading to better collaboration and fewer misunderstandings.

4. Automatic Documentation

CAD software generates detailed documentation as part of the design process, including materials, dimensions, tolerances, and specifications. This automated output reduces manual work and provides consistent records that can be used for quality assurance, approvals, and compliance.

Well-documented designs also minimize repetitive questions and improve coordination across departments.

5. Built-In Manufacturing Data

A solid CAD model acts as a roadmap for manufacturing. From material selection to production methods, CAD helps identify what’s needed to bring a design to life. It provides a bill of materials (BOM), helps estimate production costs, and ensures compatibility between design intent and manufacturing capabilities.

This integration prevents design-for-manufacturing (DFM) issues and promotes smoother transitions from prototype to production.

6. Secure Design Storage and Access

One of the most overlooked benefits of CAD is the ability to store and manage design files securely. Whether you’re designing in-house or outsourcing work, CAD ensures that your data is accessible for future updates, modifications, or legacy project reviews.

The Bigger Picture: Why CAD Matters

CAD doesn’t just make life easier for designers—it also empowers your entire product development team. From prototyping and engineering to quality control and manufacturing, CAD enhances every stage of the process. Projects are completed faster, with fewer errors, and at a higher standard of quality.

To get the most out of CAD, check in regularly with your design team. Make sure they’re equipped with the right tools, training, and support to take full advantage of this powerful technology.

Ready to modernize your design process?

Partnering with a CAD-driven engineering firm could be the competitive edge your business needs.

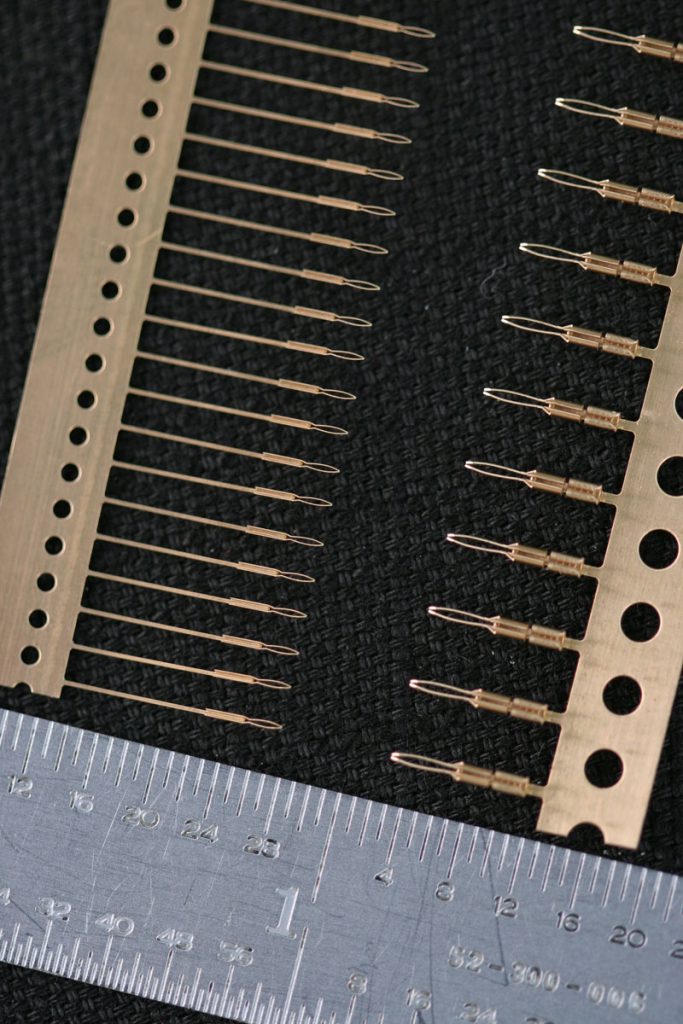

For all of your Metal Stamping needs contact Metric Tool & Stamping Inc, located in Coon Rapids Minnesota serving the entire Twin Cities MN area.