Precision Metal Stamping

Precision Metal Stamping

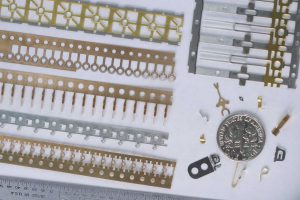

Metal stampers use high-speed presses, stamping dies, and other tools to create more accurate complete and semi-complete parts. Precision metal stamping is a new development that allows for the rapid and accurate completion of complex stamping applications using a variety of drawing, folding and stamping techniques.

Precision Metal Stamping: Benefits

Precision stamping offers a number of benefits. The highly automated process is cost-effective, particularly as production increases.Metal stamping is the preferred method for large-scale metal production.

Complex Metal Work

Precision stamping has grown in popularity due to advances in stamping technologies. This allows for highly accurate parts by using tools. This is an excellent way to design:

- Engine components for sensitive automotive and aerospace engines

- Aircraft navigation equipment and radar

- Machine Gears

- Surgical Instruments

Metalworkers have been able to improve precision stamping through technological advancements. Here are some ways that manufacturers can achieve greater accuracy in their parts.

- Metalworkers can create 3D shapes such as squares, shells and cylinders using deep-drawing stamping.

- The same die is used for both in-die extrusion as well as tapping. This eliminates the need for secondary operations such as welding nuts.

- Progressive die design applies cutting-edge software to advance die creation

- When stamping complex geometries, transfer stamping reduces secondary operations and costs.

Prototype Design

Metal stamping is used by many companies to perform prototyping and tests. Stamping machines that are computer-programmed can quickly incorporate changes to the design into the product. This allows you to produce several different versions of a component within 1-2 days.

Prototypes and their Types

Progressive Strip Prototyping

A die guides stock prototype material throughout the manufacturing process. The workpiece is moved through the stations by manual or automatic feeders. At the end, the product is complete. This automation capability allows you to use progressive strip prototypes to produce small parts with tight tolerances and quick turnarounds.

Single Part Transfer Prototyping

The individual prototypes are moved manually from one station to another. Each station forms or blanks a piece in accordance with programmed instructions. If the company uses a standard design, this method can reduce tooling costs.

Metal Stamping at Metric Tool and Stamping

Metric Tool and Stamping is always looking for ways to refine and improve our products and processes. We strive to use the most environmentally friendly manufacturing methods possible and reduce our energy consumption and waste.

Contact us to find out more about our precision metal stampeding services.