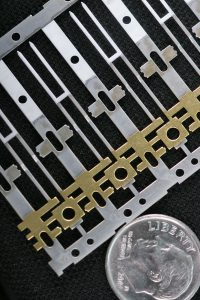

Precision metal stamping parts are used by people in their daily lives. Precision metal stamping parts are highly demanded in the electronics sector. You need to improve precision metal stamping part quality and production requirements if you want to use precision stamping parts in a larger range.

Precision metal stamping parts are used by people in their daily lives. Precision metal stamping parts are highly demanded in the electronics sector. You need to improve precision metal stamping part quality and production requirements if you want to use precision stamping parts in a larger range.

How can we improve the production requirements of precision metal stamping parts?

- Material selection

The selection of materials is crucial to the quality and precision of precision stamped parts. Metal materials that are plastic and tough should be used during the production process. Examples include stainless steel, aluminum alloys, etc. These materials will ensure that the stamped parts do not break or deform when under stress.

- Mold Design

The design of molds is an important aspect of metal stamping. Designing the mold must take into consideration the size, shape, accuracy and other aspects of the product. To ensure the accuracy of stamping parts and their surface quality, the manufacturing process for the mold must be controlled strictly. The service life of a mold is another important factor that requires regular maintenance to prevent product quality from being affected by wear or other factors.

- Technical Control

The technical control is essential to ensure that stamping parts are produced with high quality. The process flow must be followed during the production process to ensure accuracy and stability. We should, for example, pay attention to parameters such as the stamping speed and pressure and stamping time to avoid problems like cracks and deformations during the stamping procedure.

How to improve the quality of metal stamping parts

- Keep the surface clean. Before processing, the blanks for precision metal stamped parts should be cleaned to avoid the surface of the die and the material being dirty. This will cause the surface to be crushed and affect the final product’s quality.

- To avoid the possibility of abrasions on the surface of workpieces during processing, it is advisable to grind and polish the die-fillet radius.

- Use only lubricating oils suitable for stamping. Filter the lubricating oils if necessary to prevent mixing impurities.

- We can only produce precision metal stamped parts that meet requirements if we strictly control quality. Precision metal stamping will become more accurate and reliable with the improvement of technology and processes.

Your Perfect Precision Stamping Company

Metric Tool and Stamping, a manufacturer of precision stamped parts, is a stamping company with years of experience. It has a wealth of experience with precision high-speed stamped parts and is specialized in developing difficult products. The production cycle is shortened, efficiency is high and unit production capacity has increased.