Metal stamping is a method of forming sheet metal into various shapes by using dies and stamping presses. Blanks, or pieces of flat sheet metal, are fed into a stamping press, which uses a tool and die surface to mold the metal into a new shape. Stamping services are provided by production facilities and metal fabricators who position the material to be stamped between die parts and apply pressure to shape and shear the material into the appropriate final shape for the product or component.

Metal stamping is a method of forming sheet metal into various shapes by using dies and stamping presses. Blanks, or pieces of flat sheet metal, are fed into a stamping press, which uses a tool and die surface to mold the metal into a new shape. Stamping services are provided by production facilities and metal fabricators who position the material to be stamped between die parts and apply pressure to shape and shear the material into the appropriate final shape for the product or component.

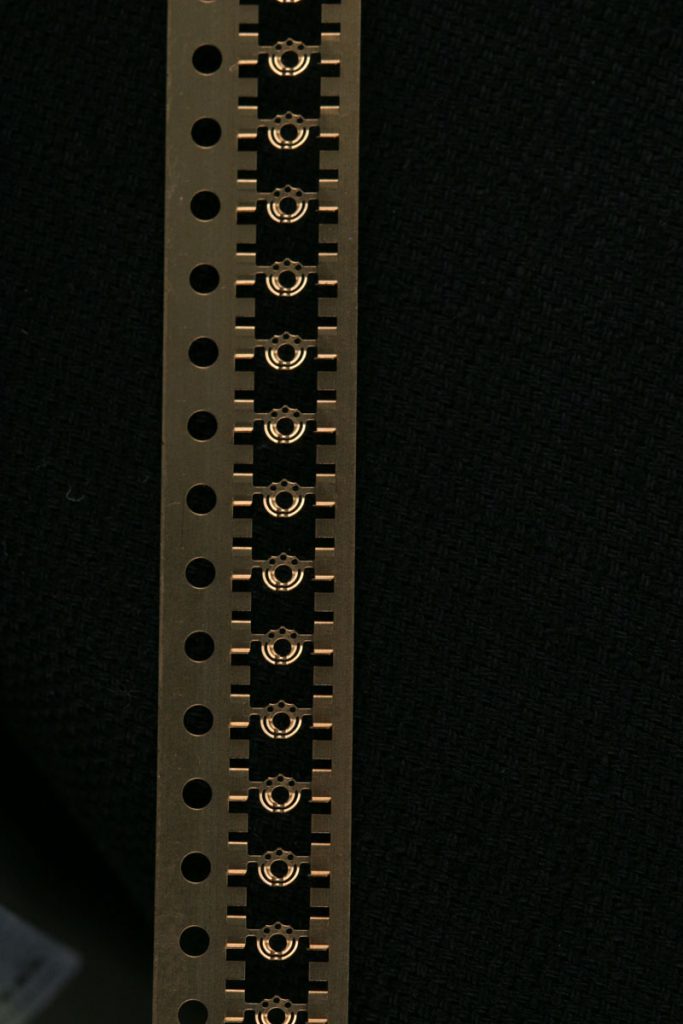

Metal stamping, often known as pressing, is a low-cost, high-speed manufacturing method that can manufacture a large number of identical metal components in a short amount of time. Stamping operations can be used for both short and long production runs, and they can be combined with other metal forming processes.

Metal stamping machines are capable of much more than simply stamping. Different tooling machines for the stamping dies are available. Specific stamping needs are met by progressive, forming, compound, and carbide tooling. Progressive dies can be used to simultaneously create many parts on a single piece.

The metal stamping materials used are determined by the desired characteristics of the produced object.

Stamping is commonly used to create the following metals and metal types:

- Silver, gold, and platinum are examples of precious metals.

- Iron-based alloys, such as stainless steel, are ferrous metals.

- Bronze, brass, and zinc are nonferrous metals.

- Beryllium nickel and beryllium copper are non-standard alloys.