Precision stampings are recognized as a complex set of metalworking processes involving the production of small, intricate components. These components have tight tolerances, requiring slots with a minimum width of 0.25 millimeters and an accuracy of +/- 0.05mm. In fact, some manufacturers demand even more stringent specifications!

Precision stampings are recognized as a complex set of metalworking processes involving the production of small, intricate components. These components have tight tolerances, requiring slots with a minimum width of 0.25 millimeters and an accuracy of +/- 0.05mm. In fact, some manufacturers demand even more stringent specifications!

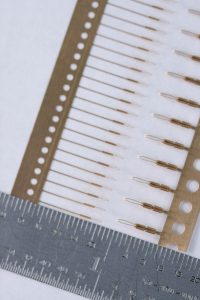

Precision stampings require fine surface finishes (measured in microinches), small radius end points, and protruding tabs or tails that can support their own weight while being handled by automated equipment.

This blog post will explain why precision stampings are becoming more difficult to manufacture, as well as the obstacles you may face when attempting to implement them in your production line.

What is an Exact Stamping?

A precision stamping is a metal component formed using a die or punch to conform to a specific shape.

It is a highly automated process that involves cutting a sheet of metal to size, then feeding it into a machine that presses it into a specific shape. The process is highly adaptable in that it permits the fabrication of numerous different parts from a single metal sheet.

Miniature precision stampings require minimal finishing operations. Electrical connectors, printed circuit boards, medical supplies, and automotive components such as air bag sensors are common examples of precision stampings. These items are anticipated to be durable, dependable, and lightweight.

Why Are Precision Stampings Getting Harder to Manufacture?

For decades, manufacturers have utilized precise stamping techniques. China, Japan, and Taiwan account for the majority of these manufacturers. As these businesses have grown, they have been able to manufacture more precise stampings than ever before. This has resulted in a global surplus of precision stampings, which has significantly reduced the price of the products.

Sadly, this trend has also led to the closure of many factories. Because the price of precision stampings has decreased so drastically, it has been difficult for Western manufacturers to compete in this market.

Whether you’re a manufacturer in the West or the East, you’ve probably noticed that it’s harder than it used to be to produce precise stampings.

3D Measuring Information is Required

The creation of precise stampings is guided by a specific set of design drawings. To ensure that the component is manufactured correctly, these drawings must be converted into a 3D model. In addition to SolidWorks, Inventor, AutoCAD, and Fusion 360, there are numerous 3D modeling software packages on the market.

These programs enable you to create virtual drawings of the component, which can then be converted into a millimeter-accurate 3D model. When manufacturing a component, it is crucial that the 3D model and the corresponding drawings are identical. If the software used to design the part is inaccurate, the manufactured part will also be inaccurate.

Machine Accuracy Is Extremely Crucial

The pressing machine is the first and most obvious piece of equipment that must be precise.

According to the International Organization for Standardization (ISO), the accuracy of the machine must be within 0.020 inches. This accuracy requirement may not appear extraordinary at first glance. Due to the small size of the manufactured component, this margin of error corresponds to a tolerance of just over 0.005 inches! This is an extremely tight tolerance, but the part will not be manufactured correctly if the pressing machine is not accurate to this degree.

Tooling Tolerance is typically quite low.

The tooling is another important aspect of the precision stamping production process. The tooling consists of a specific die or punch designed to shape the metal into the desired part. Frequently, the tooling is manufactured overseas, but it must be inspected to ensure it meets the required precision standards.

If the tooling is not precise enough, the part will not be manufactured to the required specifications.

For instance, the width of a 0.25 millimeter slot must be within 0.002 inches. This is equivalent to two standard copy paper sheets (16 sheets total). The required tooling tolerance varies depending on the manufactured part, but is typically quite small.

Consistently Quality Tools Produce Consistently Quality Parts

If the intended slot width of the part is 0.25 millimeters, the die or punch must be able to create a 0.25 millimeter-wide slot. If the tolerance of the die or punch is +/- 0.005 inches, the slot will measure 0.22 millimeters. This is a problem for both the manufacturer who produces the component and the customer who purchases it. Therefore, it is essential to choose tools with a tolerance of +/- 0.005 inches. If the tooling has a tighter tolerance, the manufactured part will have the correct slot width. Slot width can fluctuate if the tooling has a looser tolerance.

Conclusion

Precision stampings are intricate processes that necessitate the use of specialized equipment and analytical expertise. For instance, the pressing machine must be calibrated to ensure that the component is punched according to the die. Because these parts are manufactured with tight tolerances, it is essential to confirm the accuracy of the equipment used to produce them. Producing precise stampings is more difficult than ever before. It is now required to use 3D modeling software to create virtual drawings of the component and convert this data into a 3D model. To ensure that the part is manufactured correctly, the 3D model must match the original drawings. Lastly, it is essential to choose the appropriate manufacturing tools.