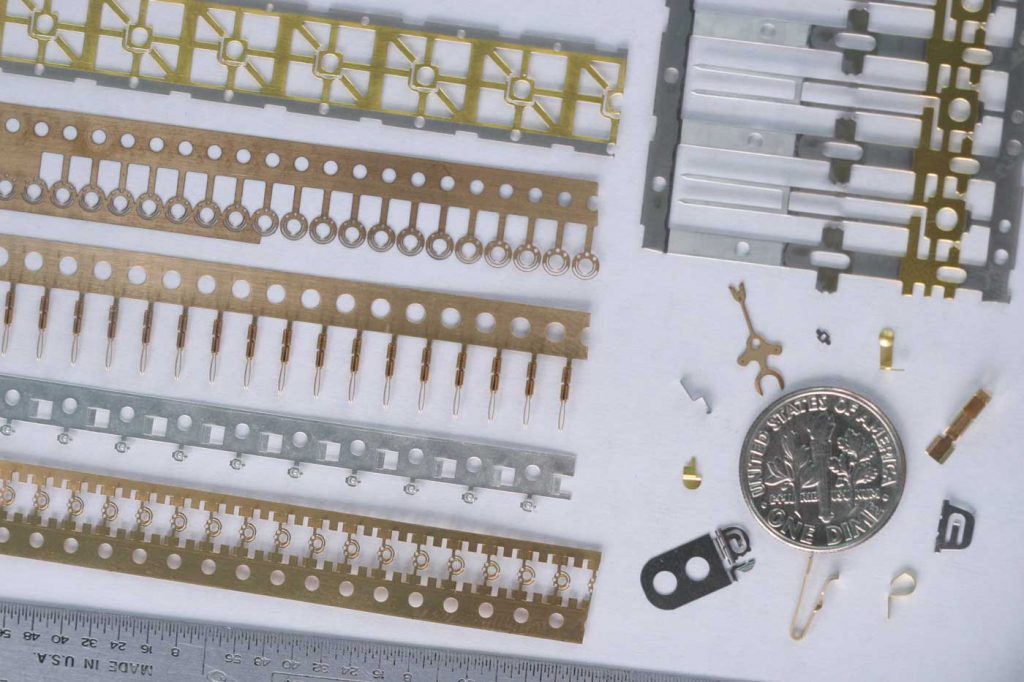

As opposed to regular stamping parts, high speed precision metal stamping parts are more complex in terms of shape, strength and rigidity. The applications of precision metal stamping include but aren’t limited to instruments, electrical appliances, measuring equipment and tools, computers, telecommunications equipment and many more such items. Here are a few methods of inspecting […]

Tag: precision manufacturing and design

Understanding Computer-Aided Design

Computer-Aided Design or CAD refers to any type of software use involving the optimization, creation, and/or modification of specific parts. The software helps create efficiencies to ensure the overall design functions as intended. This can include variations in how designs are created and what type of documentation is established for the various parts. CAD software […]

A Closer Look At The Intricacies Of Metal Stamping

There is quite a lot more to metal stamping than people generally realize. For instance, there are a number of steps needed to create complex metal stamping parts. Even parts that seem simple upon a cursory glance often need more than a single stamping step in order to be fully finished. There’s often a lot […]

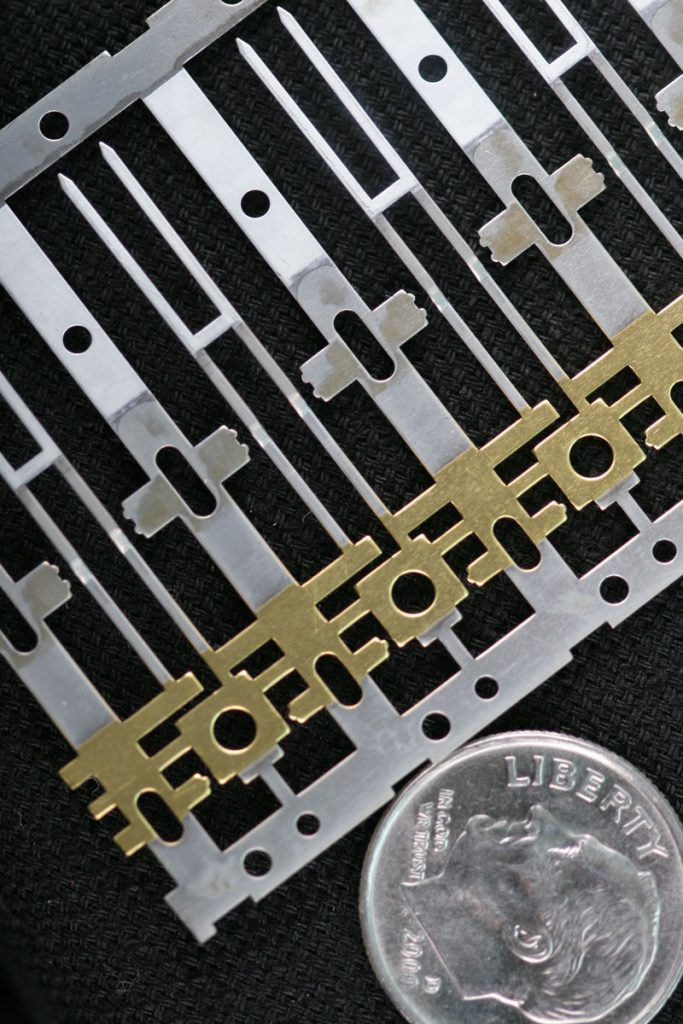

The Progressive Die Stamping Process

The progressive die stamping process is used for converting a flat strip of metal into useful parts as per the print specifications. As the name suggests, a progressive stamping die is used in this process. It is a metalworking device. Essentially, progressive die stamping may be defined as a cutting and forming process wherein sheet […]

Understanding Metal Stamping

Although a few processes use heated material, metal stamping typically takes cold metal and puts it in-between dies. By pressing the material, you can form the desired shape from the metal. These shapes usually create components or tools for bigger formations. Sometimes, “pressing” is a term used to refer to metal stamping by some individuals […]

Reasons Why Every Industry Needs Precision Metal Stamping

Precision metal stamping is generally a unique industrial procedure that applies machinery affixed with dies to modify the flat sheet metal into various custom shapes. Apart from stamping, the metal presses can also carry out a wide variety of processes such as coining, flanging, embossing, bending, notching, tooling, punching, and a lot more. Precision metal […]

Stamping Presses – How do They Work?

When you want to cut or shape metal to your required specifications, you will need to use metalworking machine tools called stamping presses. In this process, the metal is drawn, trimmed, formed, blanked, and/or pierced with a die. This process can typically be used for metal that is in sheet or coil form. A stamping […]

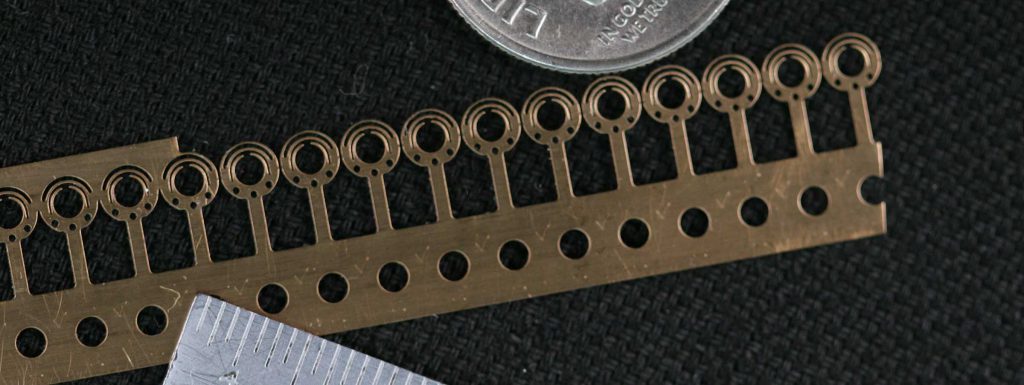

What Defines Precision Nano And Micro Stampings?

When it is time to think about the world of micro stampings, it’s important to dig deeper and understand the underlying technologies that are involved. There are several details to account for and that is where precision nano comes into play. This technology has earned praise for its high-value results and should be noted as […]

What Exactly Is Precision Stamping?

If you need to manufacture high volumes of complicated products, then precision stamping might prove to be a good answer. It’s usually pretty quick while also being very cost-efficient. Factories around the world are using three primary precision stamping applications. These are prototype design, intricate precision metalwork, and micro-precision stamping. Metal stamping is something that […]

How Are Stamping Dies Made?

Stamping dies are essential for making the sheet metal into the designs, sizes and shapes your products require. All stamping dies have two basic functions. They either cut or form metal. Some can do both. When you are in need of precision dies, you need a company that has the expertise and know-how for manufacturing […]