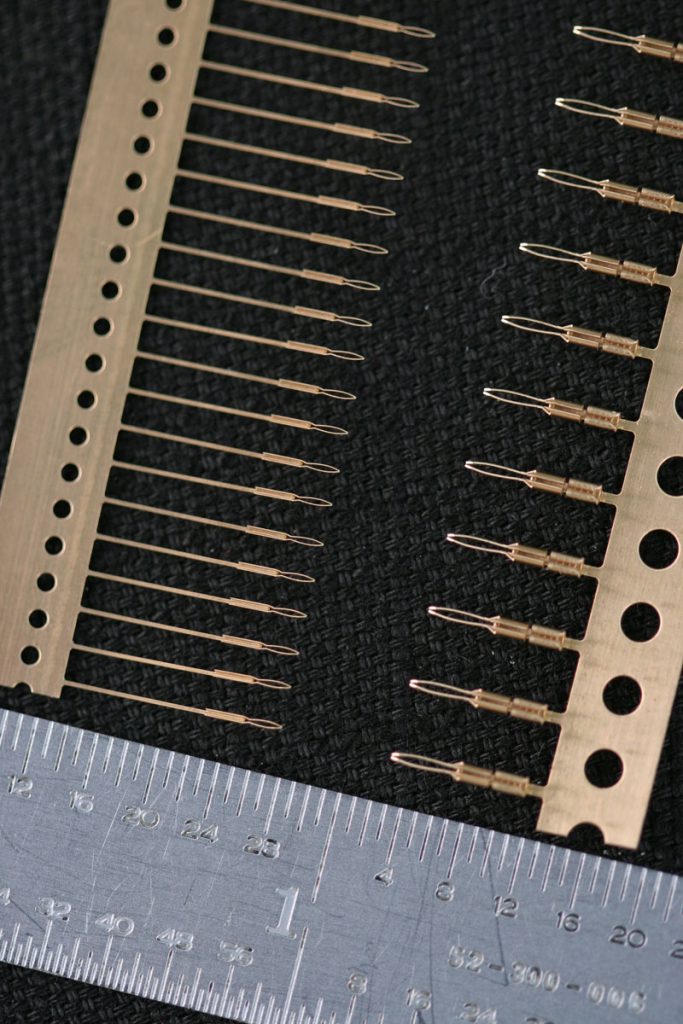

Precision metal stamping is an advanced industrial process that utilizes machinery equipped with dies to transform flat sheet metal into various custom shapes. Beyond mere stamping, these metal presses can perform an array of functions such as coining, flanging, embossing, bending, notching, tooling, punching, and more.

The Role of Precision Metal Stamping in Manufacturing

This process is integral to producing a wide range of products across various industries, including aerospace, automotive, and medical sectors. Precision metal stamping can be executed as a single-stage operation, where each press stroke yields the desired shape, or as a multi-stage process for more complex designs. As demand for precise metal parts increases, precision metal stamping has become crucial due to its ability to deliver high levels of design flexibility, enabling the creation of intricate features with tight tolerances. For all of your metal stamping needs contact Metric Tool & Stamping Inc servicing Minnesota.

The adaptability of precision metal stamping makes it particularly well-suited for custom applications, providing an excellent solution for high-volume production of sophisticated products. This method is applauded for its cost-effectiveness, speed, and flexibility, which are key advantages in today’s competitive manufacturing landscape.

Why Precision Stamping is Essential Across Industries

Precision metal stamping is invaluable in the production of accurate metal parts due to its automation potential once the equipment and dies are set up. This automation leads to two significant benefits:

- Consistent Accuracy and Quality: Precision metal stamping delivers highly precise parts, meeting the stringent precision standards required by many industries.

- Cost Efficiency in Production: The process allows for increased production levels while reducing labor costs, making it an ideal choice for the high-volume production of complex parts.

Maximizing the Benefits of Precision Metal Stamping

To fully capitalize on the advantages of precision metal stamping, several factors must be considered:

- Prototype Design: Developing prototype designs with accurate specifications is critical to minimizing deformations, defects, and errors during production.

- Material Behavior: Understanding the characteristics and behaviors of the materials used in stamping is essential for achieving optimal results.

- Technique Selection: Choosing the most suitable precision stamping techniques for the specific component being manufactured is vital to the success of the project.

Choosing the Right Precision Metal Stamping Partner

Selecting the best precision metal stamping partner involves careful evaluation of several factors beyond just cost. It’s important to consider the partner’s quality standards, experience, capabilities, and the location of their facilities. Additionally, partners that offer value-added services, such as design support and the ability to produce custom-built tools, can provide significant advantages.

At Metric Tool & Stamping Inc, we specialize in producing close-tolerance stampings, die fixturing, and custom-built tools that meet exact specifications. Our commitment to precision and quality ensures that we can meet the most demanding requirements of any industry.