Precision metal stamping is generally a unique industrial procedure that applies machinery affixed with dies to modify the flat sheet metal into various custom shapes. Apart from stamping, the metal presses can also carry out a wide variety of processes such as coining, flanging, embossing, bending, notching, tooling, punching, and a lot more.

Precision metal stamping is generally a unique industrial procedure that applies machinery affixed with dies to modify the flat sheet metal into various custom shapes. Apart from stamping, the metal presses can also carry out a wide variety of processes such as coining, flanging, embossing, bending, notching, tooling, punching, and a lot more.

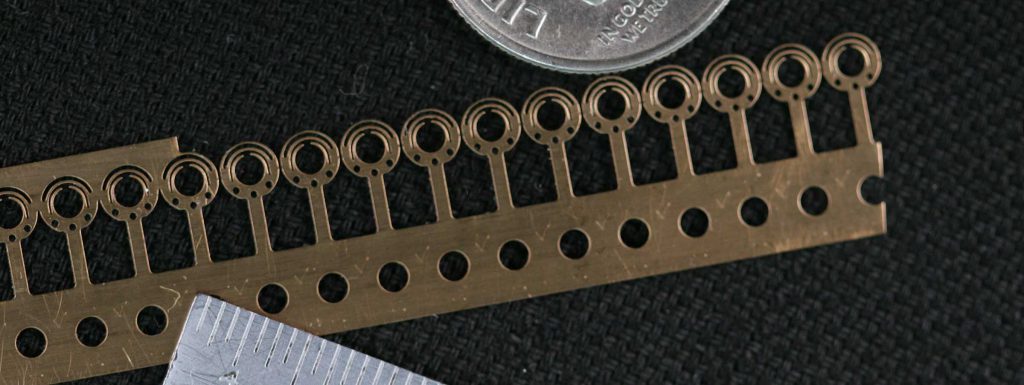

Precision metal stamping is mostly used for the production of a wide range of products. It can be performed as a single-stage activity, where each metal press stroke produces the required shape of the sheet metal, or in several stages. Due to the increase in demand for precision metal parts in different industries such as aerospace, automotive, medical, precision metal stamping has become the forefront of manufacturing. It’s because it provides a high level of design flexibility for determining and implementing certain minute features with unique configurations and tight tolerances.

Furthermore, the adaptability of precision metal stamping best serves custom applications. After all, it makes precision metal stamping an excellent option for the high-volume production of sophisticated products, all thanks to its cost-effectiveness, speed and flexibility.

Reasons Why Every Industry Needs Precision Stamping

When handling the production of accurate metal parts, precision metal stamping comes into place. After the equipment and dies are in place, the process can operate in a very automated manner. There are mainly two distinct benefits:

– Consistent accuracy and quality. Precision metal stamping allows the production of highly precise parts to the high level of precision needed in lots of industries today.

– Cost efficiency in production. Production levels increase as labour costs drop; this makes precision metal stamping an ideal option for high-volume production of sophisticated parts.

Some Considerations When Using Precision Metal Stamping Techniques

There are a few factors you need to consider to maximize the benefits that can be achieved with precision stamping techniques.

– Undoubtedly, it’s crucial to create prototype designs with the right specifications to minimize deformations, defects, and errors.

– Identify the behaviours and characteristics of the materials needed for precision stamping.

– It’s important to choose precision stamping techniques that are most suitable for the component to be manufactured.

Factors to Consider in a Precision Metal Stamping Partner

It requires careful consideration of a few factors to choose the best precision metal stamping partner. Apart from cost, one requires to take into account the partner’s quality, experience, capabilities, and location of facilities. You can also have a bonus in your decision making with extra features such as the ability of the partner to provide value-added products and design services. At MTSI, we deal with in close tolerance, stampings, and die fixturing and custom-built tool that satisfy exact specifications.