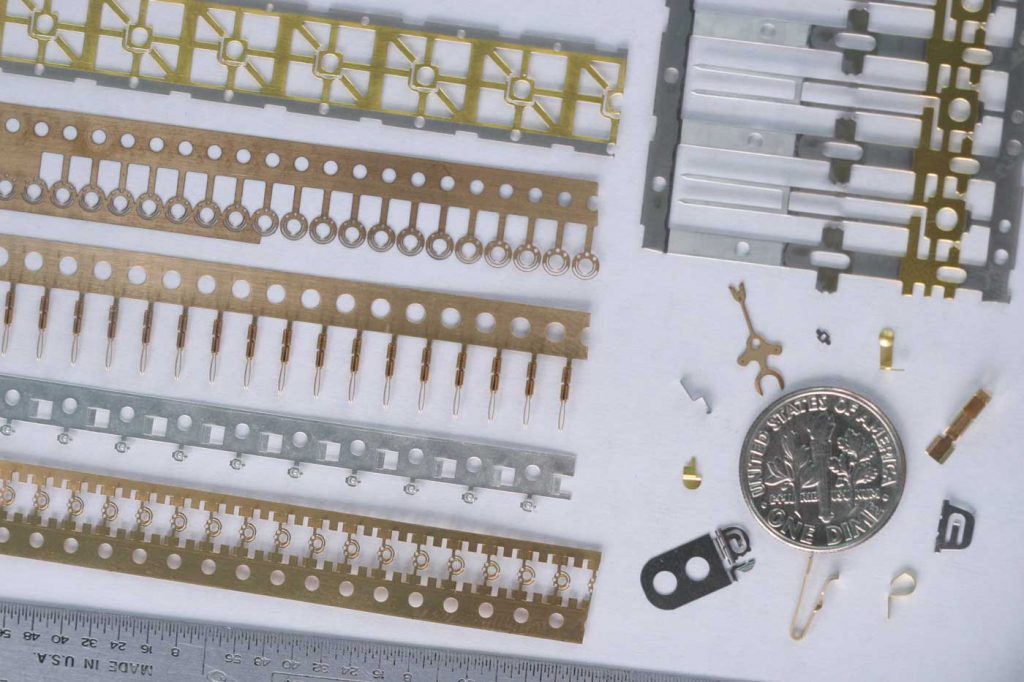

Metal stamping is a type of manufacturing process that converts a flat metal sheet into a specific shape. It is an extremely complex process that has different metal forming techniques such as piercing, bending, punching, blanking, to name a few. There are literally thousands of different metal stamping companies throughout the United States. These companies provide stamping services for industries that include aerospace, medical, automotive, and other industrial applications.

is a type of manufacturing process that converts a flat metal sheet into a specific shape. It is an extremely complex process that has different metal forming techniques such as piercing, bending, punching, blanking, to name a few. There are literally thousands of different metal stamping companies throughout the United States. These companies provide stamping services for industries that include aerospace, medical, automotive, and other industrial applications.

As we see global markets increasing and evolving, there is a strong demand for large quantity, quickly produced complex metal parts. The metal stamping process is a cost-effective and fast solution for world large quantity manufacturing stamping needs. A manufacturer who searches for specific metal stamped parts generally considers 3 important qualities which are low-cost, fast turnaround time, and high quality or durability.

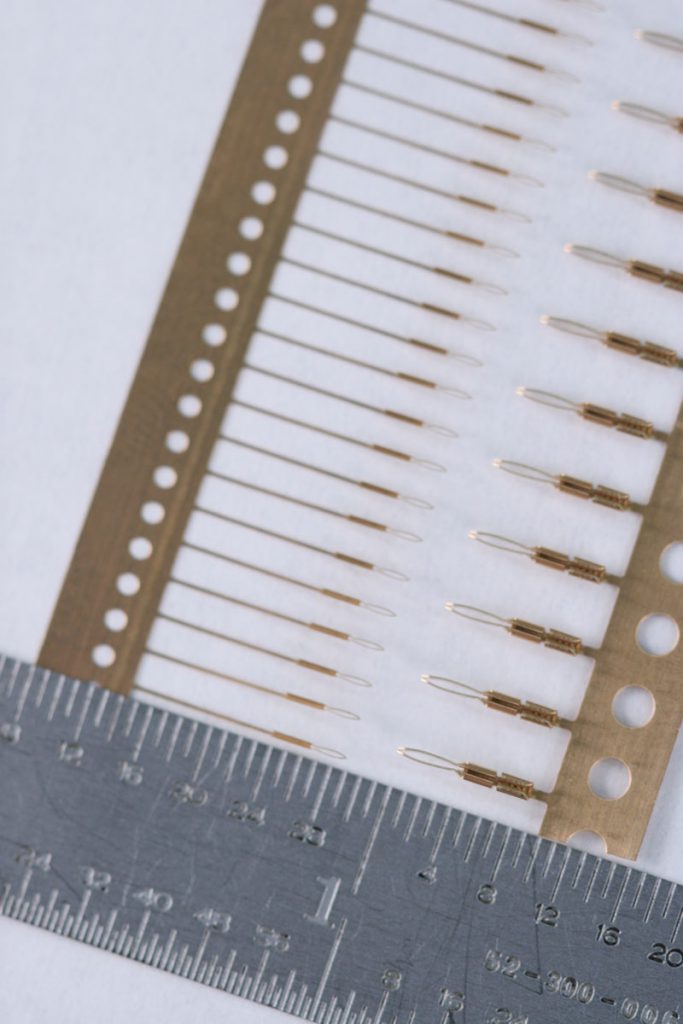

There are 3 primary types of techniques for metal stamping. They are deep draw, fourslide, and progressive. For example, a progressive die stamping process would include a number of stations and each station would have a unique function. The process begins with strip metal being fed into a progressive stamping press. The strip will unroll evenly from a coil and then into the die press. Each station will then perform a different punch, bend, or cut. Each successive station will add to the work until it becomes a completed part. The advantage of progressive die stamping include lower labor costs, shorter run length, faster turnaround, and higher repeat-ability.

A multi-slide, or fourslide, will involve 4 different slides and horizontal alignment. Basically, this type of process uses 4 different tools to simultaneously shape the metal. This type of process is perfect for complex bends and intricate cuts. There are many reasons to choose this type of stamping which include more flexibility for design changes and versatility for more complex parts

Deep draw stamping pulls a metal sheet blank into a die by means of a punch. It then forms it into a shape. This particular type of stamping is perfect for creating components that require several series of diameters. It is a cost-effective alternative to a turning process. A turning process will normally require more materials. This type of stamping is commonly used for cookware and utensils, electronic relays, aircraft parts, and automotive components.

For your next stamping project, give us a call.

Thanks for pointing out that the metal stamping process is a cost-effective and fast solution for world large quantity manufacturing stamping needs. I think that if you needed a lot of metal parts made and shaped exactly the same way it would be smart to look into metal stamping companies that could help you since it is so effective and fast. I think that could help you be more productive and that you could move things along faster in your own business. Thanks for detailing the process and benefits of metal stamping.

With metal stamping, I didn’t know that there were different methods of doing it as I thought it was all the same. It is good to see what each method is used for and how it is done as well. If I were looking to get some things stamped out, I’d for sure reference this so that I would know what method to go with.