Metal stamping is a process that uses dies and stamping presses to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, are fed into a stamping press that uses a tool and die surface to form the metal into a new shape. Production facilities and metal fabricators offering stamping services will place the material to be stamped between die sections, where the use of pressure will shape and shear the material into the desired final shape for the product or component.

Metal stamping is a process that uses dies and stamping presses to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, are fed into a stamping press that uses a tool and die surface to form the metal into a new shape. Production facilities and metal fabricators offering stamping services will place the material to be stamped between die sections, where the use of pressure will shape and shear the material into the desired final shape for the product or component.

It is also referred to as pressing, is a low-cost high-speed manufacturing process that can produce a high volume of identical metal components. Stamping operations are suitable for both short or long production runs, and be conducted with other metal forming operations.

Stamping machines do more than just stamping. Various tooling machines for the dies used in the stampings are available. Progressive, forming, compound, and carbide tooling perform specific stamping needs. Progressive dies can be used to create multiple pieces on a single piece simultaneously.

The choice of materials used depends on the desired attributes of the finished piece.

Some of the customary metals and metal types fabricated through stamping include:

Precious metals, such as silver, gold, and platinum

Ferrous metals, especially iron-based alloys like stainless steel

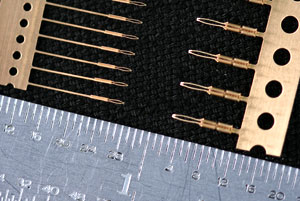

Non-ferrous metals, such as bronze, brass, and zinc

Non-standard alloys, such as beryllium nickel and beryllium copper