If you need to manufacture high volumes of complicated products, then precision stamping might prove to be a good answer. It’s usually pretty quick while also being very cost-efficient. Factories around the world are using three primary precision stamping applications. These are prototype design, intricate precision metalwork, and micro-precision stamping.

If you need to manufacture high volumes of complicated products, then precision stamping might prove to be a good answer. It’s usually pretty quick while also being very cost-efficient. Factories around the world are using three primary precision stamping applications. These are prototype design, intricate precision metalwork, and micro-precision stamping.

Metal stamping is something that utilizes high-tonnage presses, as well as stamping dies, in order to forge metal sheets into either semi- or fully-complete parts. Precision metal stamping boosts both the accuracy and speed of complicated stamping applications because it lets a product get stamped, folded, drawn, or pierced in either a single operation or a series of operations.

Advantages And Drawbacks With Precision Stamping

Precision stamping is something that can get highly automated, which makes this process a good fit for a high volume, given that labor costs will go down as the production levels go up. However, upfront tooling costs can possibly make precision stamping a poor choice for a more limited production run. Other things you should consider include the long lead times and the difficulty in making any design changes after the necessary tools are created.

What Exactly Is Micro Precision Metal Stamping?

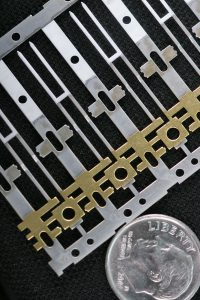

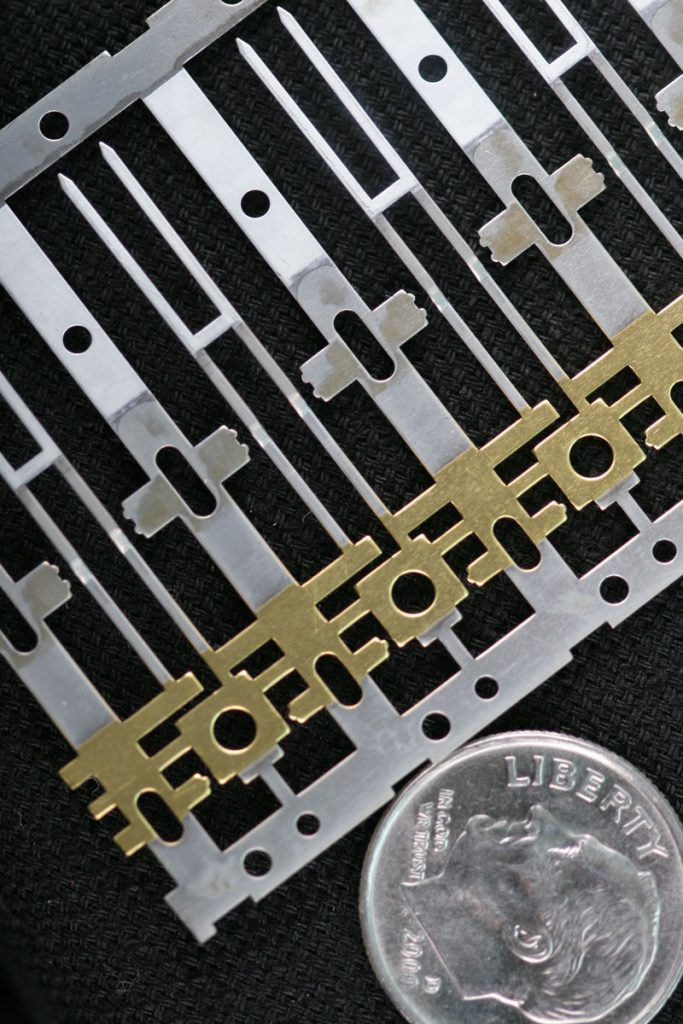

This is able to make tiny folds, bends, cuts, and stamps in a workpiece. Generally speaking, micro-precision stamping machines can support tools that have diameters as small as the micron level. The minimum diameter capabilities will vary based on the individual machine in question, but two frequently seen minimal specifications include 0.002 and 0.005 inches. Micro-stamping technology can blend 3D software with photo-etching in order to do very precise operations.

Advantages Of Micro Precision Thin Material

Aside from how effective precision micro-stamping is in making smaller parts, there are other potential advantages as well. They include but are not limited to the following:

-A Reduction In Risk: Tooling costs are lower thanks to digital and modular tooling both being included.

-Fast Results: Given the lower barriers for tooling, production might conclude in just days.

-Enhanced Versatility: Product design changes cost less time and money when compared to conventional methods of precision stamping.

It’s interesting that precision stamping provides efficient automation with a high volume of labor. My uncle is in charge of a metal factory and is thinking about implementing precision stamping in some of the operations this summer. I’ll have to share this with him so he can make an informed decision that can help his company’s efficiency and profit margins.

It’s interesting that precision stamping can help make labor costs levels go down. My uncle is thinking about implementing precision stamping in his factory to help efficiency. I’ll be sure to share this with him so he can know what to expect when making this switch.