If you’re searching for a custom engineering or design solution, partnering with a computer-aided design (CAD) firm is one of the smartest moves you can make. CAD offers numerous advantages that streamline workflows, improve design accuracy, and enhance collaboration between design and manufacturing teams. Whether you’re just exploring CAD for the first time or looking […]

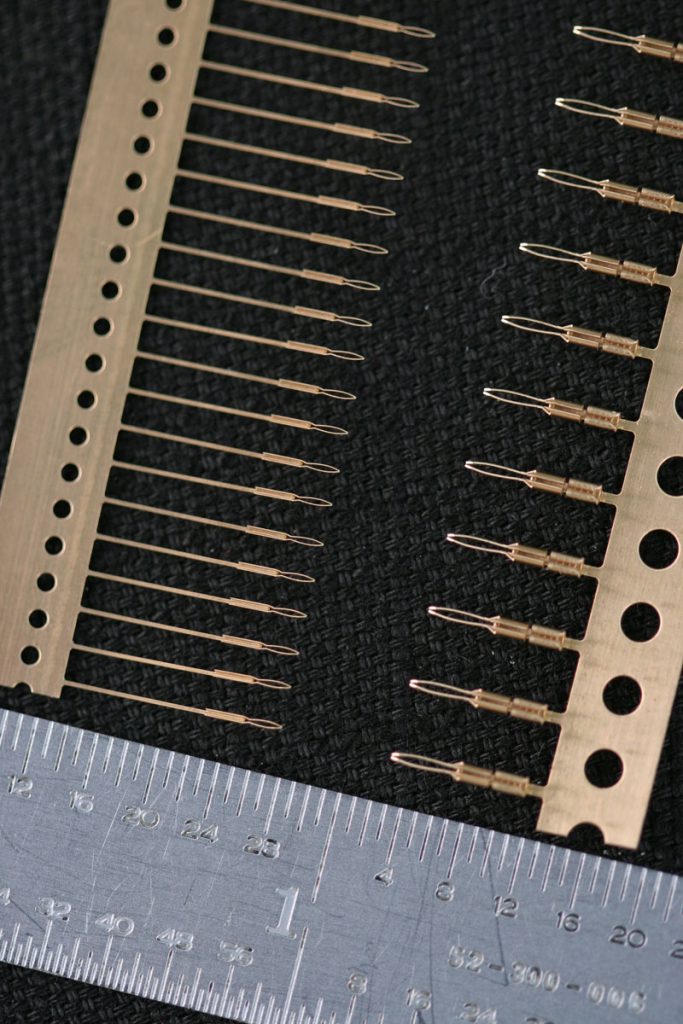

Why CAD Is Essential for Modern Design and Precision Metal Stamping