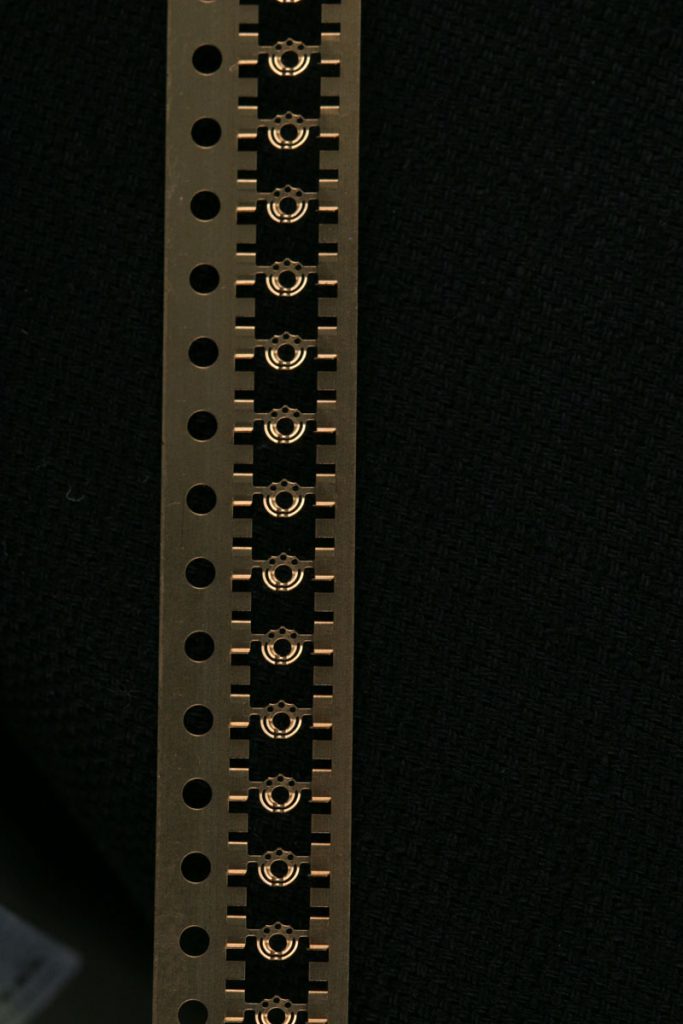

How to Make Miniature Stamped Parts Our tolerances can be as thin as a paper or even thinner! We strive to make small metal parts that are as precise as possible for your business. We can produce large quantities of small metal parts with ease thanks to our automated precision process. We can make tiny […]

Category: Precision Metal Stamping

What’s Precision Metal Stamping?

Precision metal stamping, a high-volume metalworking procedure, uses stamping tools to create sheet components from metal by forging the material into the desired shape. Each part is removed from the main sheet and stamped according to a pattern. Precision metal stamping allows manufacturers to create parts that need undercuts, multiple features or fragile walls. High […]

Tool Die Metal Stamping

Metal stamping refers to a method of making a flat sheet of metal into a specific shape. This is a complex process with many metal forming techniques, including piercing and bending, punching, punching, and blanking. There are thousands of metal stamping companies in the United States. These companies offer stamping services to industries such as […]

What are the characteristics of precision stamping machines?

Precision metal stamping is the process of punching markings, three-dimensional shapes, or other designs into material surfaces, and precision stamping machines exert a high level of force to engrave dies and forms onto the material surface. Steel, copper, and aluminum are the most frequently stamped metals, but other metals, plastics, and cement can also be […]

What Characterizes Nano and Micro Precision Stampings?

When considering the world of micro stampings, it is essential to delve deeper and comprehend the underlying technologies involved. There are numerous factors to consider, which is where nanoprecision comes into play. This technology has been lauded for its high-quality outcomes and is among the best in the industry for micro stampings. Here is a […]

Metal Tool Stamping

A sort of manufacturing procedure called metal stamping shapes a flat metal sheet into a desired shape. It is a very complicated process that uses a variety of metal forming processes, including punching, bending, blanking, and piercing, to mention a few. In the United States, there are literally thousands of distinct metal stamping businesses. For […]

Metal Stamping: An Overview

Metal stamping is a method of forming sheet metal into various shapes by using dies and stamping presses. Blanks, or pieces of flat sheet metal, are fed into a stamping press, which uses a tool and die surface to mold the metal into a new shape. Stamping services are provided by production facilities and metal […]

Frequently Asked Questions about Metal Stamping

Progressive die metal stampings are what they sound like. Custom metal stampings made with a progressive die stamping machine are known as progressive die metal stampings. Progressive die, multi slide, and deep drawn metal stampings are the three most frequent varieties. Progressive dies are the most common of the three types. What are the benefits […]

The basics of metal stamping

Do you want to hire professional metal stamping services? Having more knowledge about stamped metal will make it easier for you to choose the right company. Modern stamped metal is used for a wide range of applications, and if you need stamped metal parts, you should know what you’re paying for. You’ll learn all you […]

Stamping Metal

Some of the nation’s most successful and diverse original equipment manufacturers rely on Metric Tool and Stamping for metal stampings and assemblies. We collaborate with you throughout the design, quoting, production, assembly, inspection, packaging, and shipping processes to ensure we meet your specifications. How is metal stamping defined? With medium to high production volumes, metal […]