Computer Aided Design – The Advantages of CAD A computer-aided design firm is the best choice if you are looking for custom engineering and design companies. CAD offers many benefits to both you and your company. Find out more about the benefits of CAD here. The advantages and benefits of CAD The industry is changing, […]

Tag: precision manufacturing technology

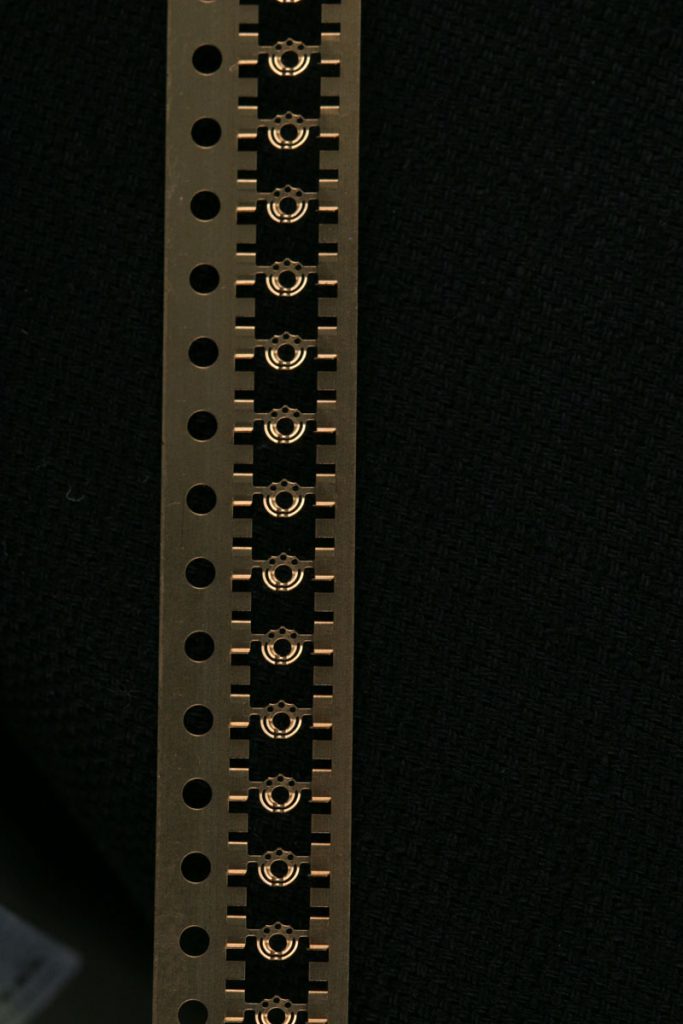

Precision Stampings: A Comprehensive Guide to Profitable Metal Stamping

Precision stampings are recognized as a complex set of metalworking processes involving the production of small, intricate components. These components have tight tolerances, requiring slots with a minimum width of 0.25 millimeters and an accuracy of +/- 0.05mm. In fact, some manufacturers demand even more stringent specifications! Precision stampings require fine surface finishes (measured in […]

What Characterizes Nano and Micro Precision Stampings?

When considering the world of micro stampings, it is essential to delve deeper and comprehend the underlying technologies involved. There are numerous factors to consider, which is where nanoprecision comes into play. This technology has been lauded for its high-quality outcomes and is among the best in the industry for micro stampings. Here is a […]

Metal Stamping: An Overview

Metal stamping is a method of forming sheet metal into various shapes by using dies and stamping presses. Blanks, or pieces of flat sheet metal, are fed into a stamping press, which uses a tool and die surface to mold the metal into a new shape. Stamping services are provided by production facilities and metal […]

Frequently Asked Questions about Metal Stamping

Progressive die metal stampings are what they sound like. Custom metal stampings made with a progressive die stamping machine are known as progressive die metal stampings. Progressive die, multi slide, and deep drawn metal stampings are the three most frequent varieties. Progressive dies are the most common of the three types. What are the benefits […]

Die Stamping

On the internet, you will find the best information about die stamping. You will learn the following: How does die stamping work? Die stamping types (progressive and transfer) Metals used for die stamping Plus much more. What is Die Stamping? A die stamping process is a cold forming technique in which a sheet of metal, […]

Custom metal stamping with full service

METRIC TOOL AND STAMPING specializes in precision metal stamping work for a quick turn-around time, heat-resistant alloys, ferrous and nonferrous metals, as well as prototypes, for both small volumes and project prototypes. Among our expertise is in the design and fabrication of in-house tools as well as product development and engineering. Metal Stamping Capabilities Stock […]

Precision Metal Stamping Process

In order to ensure proper design of complicated products or mockups, more sophisticated procedures are often needed. When faced with this problem, manufacturers look for a stamping company that uses new stamping techniques to achieve an intricate result. By using advanced technologies, it is now possible to perform cutting and engraving with a level of […]

Why choose stamping in the manufacturing of precision parts?

Precision in the manufacture of parts is becoming more and more important as technology advances. A high degree of accuracy is essential for both electronic components and automotive parts. Due to technological advancements, a demand for compact, complex products is arising, which leads to the development of high-precision parts. Manufacturers use stamping to meet the […]

Metal stamping has a positive impact on the following industries:

Nowadays, metal stamping is a pillar of many industries due to its quality and precision. This is as distinguished from metal stamping’s distant ancestors, also called forging and casting. So how is a stamped part manufactured? In short, a die is mounted to a press that cycles back and forth. Imagine it as the modern-day […]